Experience Seamless Operations Using Membrane Switch for Electronics

Experience Seamless Operations Using Membrane Switch for Electronics

Blog Article

Discover the Versatile Uses of Membrane Switch in Modern Electronic Devices

In the realm of modern electronic devices, the application of membrane layer buttons is extremely comprehensive, spanning from streamlined consumer gadgets to crucial clinical gadgets. As industries proceed to progress, the combination of membrane buttons in devices layout is pivotal, appealing not only to satisfy yet exceed the strenuous demands of both capability and visual charm.

Exploring the Role of Membrane Layer Switches Over in Consumer Electronics

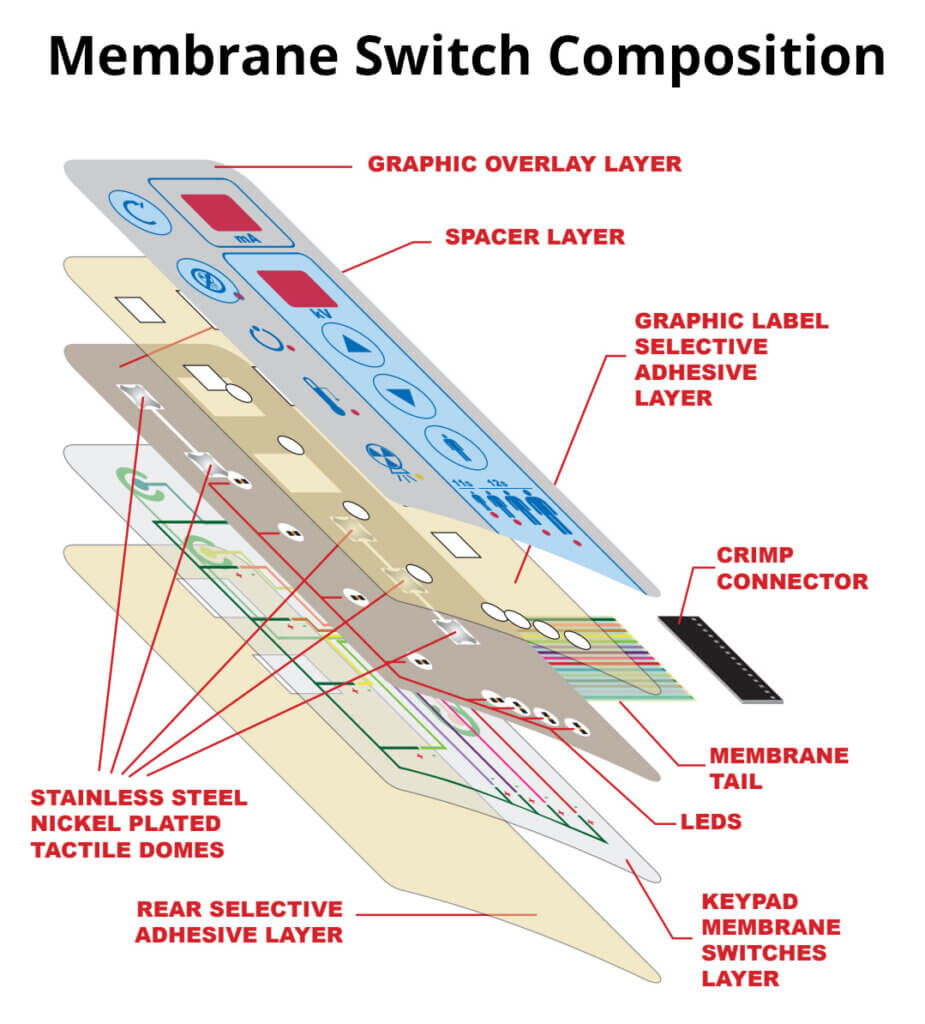

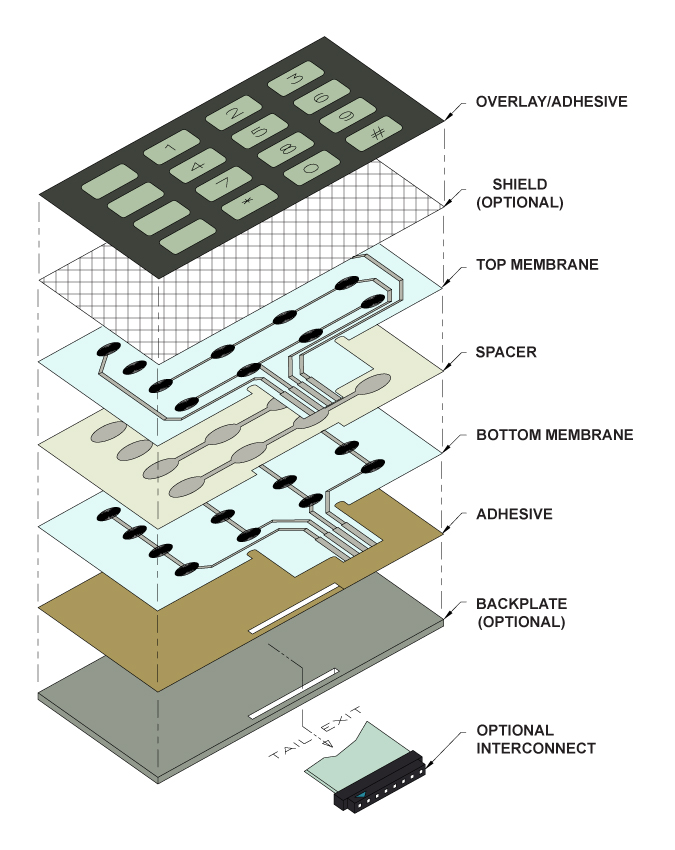

Why are membrane layer changes so widespread in customer electronic devices? The answer hinges on their unique combination of cost, adaptability, and reliability. Membrane layer buttons are economical to make, making them an appealing alternative for high-volume manufacturing typical in consumer electronic devices. Their construction, featuring a thin, adaptable layer that can conveniently be integrated right into numerous tools, permits sleek, small item layouts.

Moreover, these switches are known for their longevity and low maintenance. They are immune to wetness, dirt, and dust, which improves the long life of the electronic devices they are made use of in. This reliability is critical in daily consumer products that undertake frequent use. In addition, their flexibility in style makes it possible for customization in aesthetics and functionality, satisfying the specific needs of various digital tools. From microwave stoves to push-button controls, membrane layer buttons supply a functional, straightforward interface that sustains the dynamic nature of customer electronic devices.

Membrane Layer Switches in Medical Instruments: Enhancing Customer Interfaces

Membrane layer switches additionally play a substantial function in the world of clinical devices, where they improve user interfaces with their distinctive advantages. These buttons are especially valued for their reliability and simplicity of sanitation, crucial in medical care environments where sanitation is critical. The smooth, covered surface of membrane layer switches permits very easy disinfection, minimizing the threat of contamination and spread of pathogens. Their design adaptability accommodates the ergonomic and visual demands of medical equipment, making gadgets more instinctive and obtainable for medical care experts.

Membrane layer buttons also add to the sturdiness of clinical tools. Their resistance to fluids and contaminants guarantees that critical tools continues to be functional in different medical setups, including surgical procedures where direct exposure to fluids prevails. This toughness, coupled with tactile responses continue reading this and low-profile style, makes membrane switches an indispensable part in enhancing the effectiveness and my link safety and security of clinical device user interfaces.

The Impact of Membrane Turns On Industrial Equipment Design

In the realm of commercial equipment style, the unification of membrane layer switches has actually noted a considerable advancement. These buttons have changed how suppliers approach interface functionalities, using a mix of toughness and flexibility that is crucial in severe settings. The slim profile of membrane switches over enables more small equipment designs, while their resistance to water, chemical, and dust impurities makes them perfect for commercial setups. This adaptability has assisted in the development of devices that is not just extra robust however also much easier to keep and tidy, thus minimizing downtime and functional prices.

In addition, the customizability of membrane switches over allows developers to incorporate specific responsive feedback and graphical overlays that boost the individual experience and increase efficiency. This combination supports drivers in accomplishing precision control over complex equipment. The total effect is a considerable improvement in the capability, reliability, and user-friendliness of industrial devices, straightening with the increasing needs for technological improvement and operational efficiency in modern sectors.

Final Thought

Membrane layer buttons have transformed modern-day electronic devices, using sleek, sturdy, and adjustable user interfaces across various fields. This innovation not just fulfills the demanding problems of various fields but additionally significantly boosts individual experience, making membrane changes a cornerstone of modern electronic style.

In the world of contemporary electronic devices, the application of membrane This Site switches is remarkably considerable, covering from streamlined consumer devices to crucial clinical devices.Why are membrane layer switches so widespread in customer electronics? Membrane buttons are cost-effective to make, making them an appealing option for high-volume production regular in consumer electronic devices. From microwave stoves to remote controls, membrane buttons offer a sensible, user-friendly interface that sustains the vibrant nature of consumer electronics.

Report this page